Page 17 - Mobile_EN_WEB

P. 17

ELECTRONICS SOFTWARE

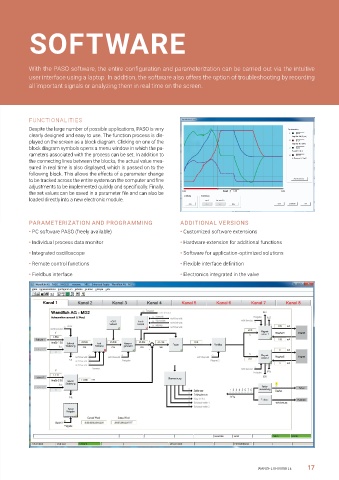

Electronic control units are required to control proportional valves. They control and regulate the solenoid cur- With the PASO software, the entire configuration and parameterization can be carried out via the intuitive

rent on the valve and thus ensure very sensitive actuation of the valve. Control units are available in a wide user interface using a laptop. In addition, the software also offers the option of troubleshooting by recording

variety of designs to meet the requirements of different tasks in various areas of application. all important signals or analyzing them in real time on the screen.

AMPLIFIER / CHARACTERISTIC FUNCTIONALITIES

REGULATOR CONTROLS MD2 Digital amplifier and controller module for use in harsh environ- Despite the large number of possible applications, PASO is very

ments. The device provides up to 8 solenoid outputs for control clearly designed and easy to use. The function process is dis-

and regulation tasks of all kinds. played on the screen as a block diagram. Clicking on one of the

block diagram symbols opens a menu window in which the pa-

FEATURES rameters associated with the process can be set. In addition to

• Robust and compact design • Up to 4 analog and 4 digital the connecting lines between the blocks, the actual value mea-

with protection class IP67 inputs sured in real time is also displayed, which is passed on to the

following block. This allows the effects of a parameter change

• Solenoid outputs can be • Up to 10 digital outputs to be tracked across the entire system on the computer and fine

used as proportional or swit- adjustments to be implemented quickly and specifically. Finally,

ching solenoid outputs • Optionally with CANopen

field bus the set values can be saved in a parameter file and can also be

• Set values in the form of loaded directly into a new electronic module.

voltage, current, frequency, • Screw fastening of the

PWM housing

PARAMETERIZATION AND PROGRAMMING ADDITIONAL VERSIONS

VALVE ELECTRONICS DSV CHARACTERISTIC • PC software PASO (freely available) • Customized software extensions

Digital amplifier electronics DSV (Digital Smart Valve) integrated • Individual process data monitor • Hardware extension for additional functions

directly in the valve to control a proportional valve.

• Integrated oscilloscope • Software for application-optimized solutions

FEATURES • Remote control functions • Flexible interface definition

• Amplifier or controller type • 2 digital inputs and 1 output • Fieldbus interface • Electronics integrated in the valve

• Controller modes selectable: • Can be parameterized using

pressure, position, speed PASO software

• Valve set at the factory • Optionally with fieldbus

(CANopen, Profibus DP)

• Control via solenoid current

with dither signal • Protection class IP67

• Set values as voltage or

current

MINIATURE AMPLIFIER PD2, PD3 CHARACTERISTIC

Digital amplifier module for controlling a proportional valve. PD2 is

an electronic unit with cable connection. In the MPS version, it is

permanently mounted on a solenoid.

FEATURES

• Housing IP67 • Can be parameterized using

PASO software or display

• Solenoid current controlled and buttons on the device

• Setpoint as voltage or • Optionally with fieldbus

current (CANopen or J1939)

• Digital input • Housing with cable connec-

tions or mounted on solenoid

16 WANDFLUH MOBILE WANDFLUH MOBILE 17